Search Product

Structure Search

Search

Advantage Products

Location: Industrial Info

CAS:115-70-8| The application of AEPD in polyurethane foam

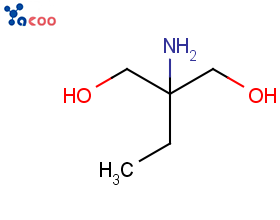

Product Name: 2-Amino-2-ethyl-1,3-propanediol(AEPD)

CAS:115-70-8

Molecular Formula: C5H13NO2

Article No.: A0071

Structural Formula:

Product Introduction

AEPD is a biochemical reagent with a molecular weight of 119.16, soluble in water. AEPD can be used as an additive in aqueous suspensions to improve the conductivity of suspensions, can be used as an alkalizing agent in hair forming compositions, can also be used as a component of polyurethane foam, and can also be used in inks.

Application of AEPD

Polyurethane rigid foam is a kind of low-density microporous polymer foam with closed cell structure. It has been widely used in the fields of architecture, electronics and electrical, chemical coatings, etc. due to its excellent chemical resistance, low toxicity, good mechanical properties and electrical insulation. In the electrical field, people often use polyurethane rigid foam as the anti condensation gas sealing material, such as the anti condensation gas sealing material for terminal box type substation, wind box type substation, photovoltaic box type substation, high-speed railway special box type substation and other electrical equipment, which has the advantages of good sealing effect, convenient operation and low cost. However, because the blocked power equipment is often exposed to the sun, and the polyurethane rigid foam is vulnerable to aging due to the influence of ultraviolet light, which leads to the decline of mechanical performance, surface embrittlement, and the decline of airtight sealing effect, there is a great potential safety hazard in the work of power equipment. It is of practical significance to develop a UV aging resistant airtight plugging polyurethane foam. Therefore, CN116253861A developed a spray airtight plugging polyurethane foam and its preparation method. The polyurethane foam consists of component A and component B, specifically:

Component A includes the following raw materials by weight: 100 parts of polymer polyol, 1-5 parts of water, 1-3 parts of small molecule polyol, 3-5 parts of fluorine-containing diols, 2-6 parts of catalyst, 1-3 parts of foam stabilizer;

Component B includes 1,5-naphthalene diisocyanate and polymeric MDI.

Fluorinated diols are synthesized by reacting fluorinated esters with amino glycol compounds, which are selected from one or more combinations of 3-amino-1,2-propanediol, 2- (aminomethyl) -1,3-propanediol, 2-amino-2-ethyl-1,3-propanediol, and serinol.

By introducing fluorine-containing diols as chain extenders into the raw materials of component A in the preparation of polyurethane, the UV resistance is better. Amide bonds are formed in the hard segment of polyurethane, which are easy to form hydrogen bonds with amino acid ester bonds, resulting in better orientation of amino acid ester hard segments, ordered crystallization, more perfect crystallization, and increased crystallinity, thereby improving UV resistance, At the same time, the stability of mechanical properties and working safety of polyurethane foam are improved; By introducing 1,5-naphthalene diisocyanate as an isocyanate into the raw material of component B, the hard segment of polyurethane contains a naphthalene ring, which further improves the UV resistance of polyurethane.

References

CN116253861A The invention relates to spraying airtight plugging polyurethane foam and a preparation method thereof.