Search Product

Structure Search

Search

Advantage Products

Location: Industrial Info

CAS:409071-16-5| The Application of LiODFB in High Pressure Flame retardant Electrolytes

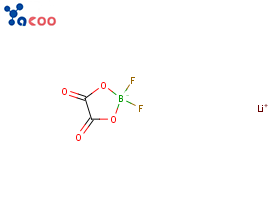

Product Name:LiODFB

CAS: 409071-16-5

Molecular Formula:C2BF2LiO4

Article No.:E0523

Structural Formula:

Product Introduction

Lithium Difluorooxalate (LIODFB) is a white powder or crystalline substance. LIODFB is highly soluble in water, has strong hygroscopicity, high cycle life, power supply capacity, and low temperature and high rate performance of batteries. It is a high-performance salt for lithium-ion batteries. LIODFB can be used as a film-forming additive or to replace lithium hexafluorophosphate as a conductive salt in lithium battery electrolytes. It can also stabilize the solid electrolyte interface on the surface of graphite anodes and improve the cycling efficiency and capacity retention ability of batteries as an additive.

Application of LiODFB

Since the emergence of lithium-ion batteries, they have been widely used in electronic communication fields such as mobile phones, laptops, and digital cameras due to their high energy density, good cycling performance, no memory effect, and green environmental protection. After continuous development, the application of lithium-ion batteries in the field of electric vehicles is showing a rapid upward trend. With the popularization of electric vehicles, there is an increasing demand for power lithium batteries applied in electric vehicles, which have a broad market and application scenarios. Nowadays, the energy density requirements for lithium batteries are increasing, so the use of high-voltage cathode materials is an important direction. Electrolyte is the most important component of lithium batteries. Conventional electrolytes will oxidize and decompose under high pressure, causing the cycling performance of high-voltage lithium batteries to quickly deteriorate, thereby limiting the development of high-voltage cathode materials. One of the main reasons for the frequent occurrence of spontaneous combustion accidents during the charging of electric vehicles or electric vehicles is that commercial lithium battery electrolytes are mostly organic solvents such as carbonates, which are prone to combustion and even explosion hazards under high temperatures, short circuits, and other conditions, with low safety. Therefore, the CN114373994B patent has developed a high-pressure flame-retardant electrolyte and its preparation method and application aimed at solving the problems of existing commercial electrolytes that are not resistant to high pressure and flammable.

The high-pressure flame retardant electrolyte solvent consists of C4H9F2NO4S2, C4H3F3O3(trifluoromethyl ethylene carbonate), TTE (1,1,2,2-tetrafluoroethyl-2,2,3,3,3-tetrafluoropropyl ether), and DEC (diethyl carbonate) with a volume ratio of 2:3.5:3.5:1, and LiODFB with a solute of 1mol/L.

Dissolve 0.1438g of LiODFB in a solvent composed of 0.35mL of C4H3F3O, 0.35mL of TTE, and 0.35mL of DEC. After LiODFB is completely dissolved, add 0.2mL of C4H9F2NO4S2 and stir evenly to obtain a high-pressure flame retardant electrolyte.

This high-pressure flame-retardant electrolyte is mainly composed of a fluorinated sulfone solvent, with sulfone groups and fluorine atoms having lower HOMO energy levels, which can improve the anodic stability of molecules. Additionally, the solvent molecules have a high flash point (>130 ℃) and good flame retardant performance. Moreover, fluorinated solvents can form stable SEI films rich in LiF on the negative electrode. Combined with the lithium salt solubility of other organic solvents, this electrolyte has good wettability, flame retardancy, high pressure resistance, and good interfacial film-forming properties.

References

CN114373994B A high-pressure flame retardant electrolyte and its preparation method and application.