Search Product

Structure Search

Search

Advantage Products

Location: Technique Support

isobutoxy methacrylamide (IBMA cas16669-59-3) as new printing adhesive crosslink monomer

1. Properties of IBMA

N-(isobutoxymethyl) acrylamide (IBMA) is a new kind of crosslinking monomer. Compared with N-Methylolacrylamide (NMA) which was a traditional crosslinking material, IBMA has 3 more advantages :( 1)the printing adhesive crosslink made by IBMA has more excellent resistance to water and heat, also with better flexible in printing membrane. It changed the view of printing adhesive’s hard-touch. (2) low cure energy consumption (120℃ per 5minutes). It saved 20%-25% energy by comparing with NMA preparing adhesive. (3) Isobutanol gas released was harmless to the environment during curing of IMBA, while the NMA released toxic formaldehyde. Besides, In addition to other superior performance as follows:

(1) Stickiness and tensile strength improvement

(2) High-impulse resistance

(3) More flexible(To reduce the thermosetting polymer cracking occurs)

(4) Prevent caking and bonding

(5) Soft touch

(6) For emulsion polymerization and solvent matrix resin synthesis

(7) Used as UV light curing system reaction diluents and improve the adhesive force of polar materials in the system.

2. The mechanism of IBMA’s applications in silk anti-wrinkle, preshrunk and yellowing resistance

(1) The mechanism of yellowing resistance

Japanese scholars studied, the reason of silk yellowing is that silk fibroin polypeptide chain, carrying with branched and fragrant chain amino acids such as tryptophan, tyrosine, histidine and phenylalanine, is broken up after the ultraviolet irradiation and generates the pyrolysis products containing yellow pigment. Therefore, silk fibroin polypeptide degraded after the light irradiation and turned yellow.

To prevent silk yellowing, there are two solutions. The one is adding UV absorber. While, the silk with UV absorber is intolerance of wash. The other way is to modify silk chemically with graft polymer of vinyl monomer (including the epoxides grafting).

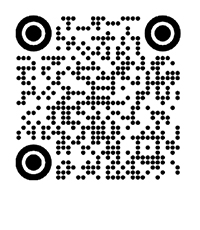

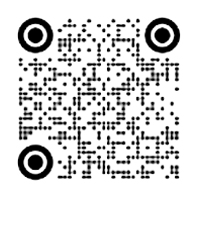

Japanese scholar Masuhiro recently studied graft polymerization of IBMA was on to silk with ammonium persulfate as initiator, polyoxyethylene nonyl phenyl ether and sodium dodecyl benzene sulfonate as emulsifier. If the polymerization reaction system pH was reduced by formic acid, the polymerization reaction would be carried out on silk surface. The oligomers of IMBA attached on silk surface absorb UV irradiation and play a role of barrier to prevent active component of UV reaching light-sensitive silk fibroin to weaken light-intensity. The oligomer attached on the silk surface is a monomer complex formed by IBMA and silk fibroin protein. The following graph showed the IBMA polymer on silk how to reduce the rate of silk yellowing under by Japanese scholar.

The relationship between yellowing degrees and light time dealing with grated silk of different polymerization degree

Note: silk material is habotai; light wavelength and intensity of carbon arc is 380nm and 490W/m2; 1-4 represent different weight gain rates of grafted silk, are separately 0, 33.9%, 18.3% and 6.7%.

(2)The mechanism of anti-wrinkle and preshrunk

IMBA aggregating with silk amino acid side chain under the trigger of persulfate changes the silk molecular structure with cross-linking bond. The part of cross-linking bond becomes framework of silk molecular structure which plays the roles of support and fixation the way the bond makes the silk vertical sense. Therefore, a moderate cross-linking will be overcome the shortcome of silk easily wrinkled and shrinkage. In addition, the bond of NH and ether combining with silk molecular peptide chain can form hydrogen bond; it reduces the combination of water and peptide chain. In this way, silk will reduce the puffing anisotropy or shrinkage after silk getting wet.