Search Product

Structure Search

Search

Advantage Products

Location: Thematic focus

CAS:33027-66-6| The Application of Ethoxypentafluorocyclophosphazene in Plastics

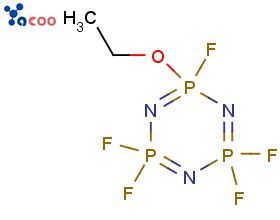

Product Name:Ethoxy(pentafluoro)cyclotriphosphazene

CAS:33027-66-6

Molecular Formula: C2H5F5N3OP3

Article No.:Y0791

Structural Formula:

Product Introduction

Ethoxy (pentafluoro) cyclophosphazene is mainly used in electronic components (flame retardant additives for battery electrolytes, battery recovery liquids, and circuit board substrates), and can also be used to synthesize materials with high flame retardancy (flame retardant silicon core bundle tubes for communication, polyethylene/polycarbonate composite materials, and inorganic/organic composite building materials). It is widely used in chemical production, electronic devices, multifunctional materials, and other fields.

Application of Ethoxy(pentafluoro)cyclotriphosphazene

Polycarbonate (PC) is an engineering plastic with excellent comprehensive performance, ranking first in impact resistance among thermoplastic plastics. It has good dimensional stability, high thermal deformation temperature (130-140 ℃), good weather and electrical resistance, and is widely used in industries such as automobiles, electronics, home appliances, and construction. The ultimate oxygen index of PC resin reaches 26%, and it can self extinguish after ignition. The commercial PC resin on the market has been evaluated for flame retardancy according to the UL94 standard in the United States, and most of them can reach the V-2 level. However, in practical applications, people hope that PC materials have better flame retardancy and can reach the V-0 level. At the same time, they also hope that PC materials have high moisture and heat resistance to meet outdoor application needs. Among the existing PC halogen-free flame retardants, traditional phosphate flame retardants such as triphenyl phosphate (TPP), resorcinol bis (diphenyl phosphate) RDP, and bisphenol A bis (diphenyl phosphate) BDP have the disadvantages of large formula addition and high process requirements; Sulfonate flame retardants have a low amount of addition, high requirements for dispersion process, and are prone to moisture absorption and poor hydrolysis stability, which may cause harm to the environment and limit their application scope; Silicone flame retardants have many advantages, such as low addition in PC, almost no loss of physical and mechanical properties of the original PC resin after modification, but limited flame retardant efficiency. In this context, CN114573970A patent has developed a polycarbonate composite and its preparation method.

The carbonate composition includes 100 parts polycarbonate, 3-10 parts phosphoric acid polymer, 1-5 parts hydrated layered silicate, 0-1 parts antioxidant, and 0-3 parts other additives. Among them, the phosphate polymer is at least one of phosphophenanthrene, phosphoronitrile, organophosphinic acid, etc. Phosphazene can be selected from at least one of the following flame retardants: hexachlorocyclophosphazene, bis (4-oxo-pentane-glycidylcyclotriphosphazene-phenyl) propane (PN-EPC), cyclophosphazene flame retardant bisphenol A bridged pentyl (aniline) cyclophosphazene (BPA-BPP), hexapara hydroxyphenoxycyclophosphazene, hexapara carboxylphenoxycyclophosphazene, hexaphenoxycyclophosphazene (HPCP), (4-diethyloxyphosphoryl hydroxyphenoxy) cyclophosphazene, ethoxy (pentafluoro) cyclophosphazene, and hexaphenoxycyclophosphazene.

The present invention adds a specific amount of phosphoric acid polymer and a specific amount of hydrated layered silicate to a specific weight average molecular weight PC resin, making it highly flame-retardant and moisture resistant, while maintaining high mechanical properties. The processing technology is simple, environmentally friendly, and suitable for industrial production and promotion. It is also suitable for preparing outdoor plastic parts, such as photovoltaics in outdoor base stations.

References

CN114573970A A polycarbonate composite and its preparation method and application.